Here are some images from my most recent prototyping work. I'm working on a surface with thick keys that should provide very consistent mechanical behavior and a nice tactile quality for the instrument.

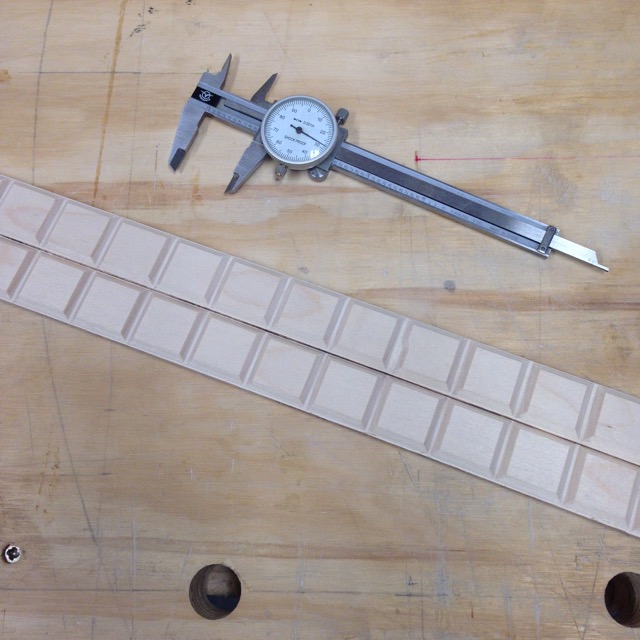

Here are some pieces of birch with v-grooves routed into them every inch.

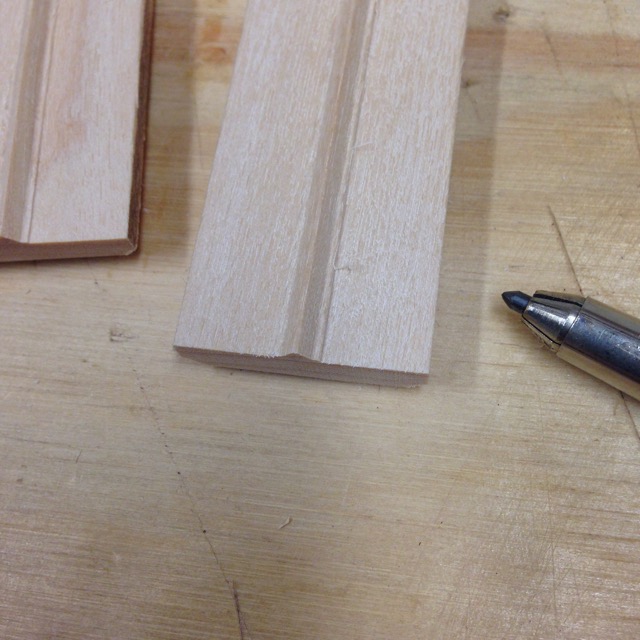

With some fine router work on the flat sides of the strips, I made this profile with a 1/16" bump in the center.

Now sanding, too much sanding. I don't like sanding.

More sanding to get the profile I'm looking for. Maybe it's my years of C++ talking but these look kind of like curly braces.

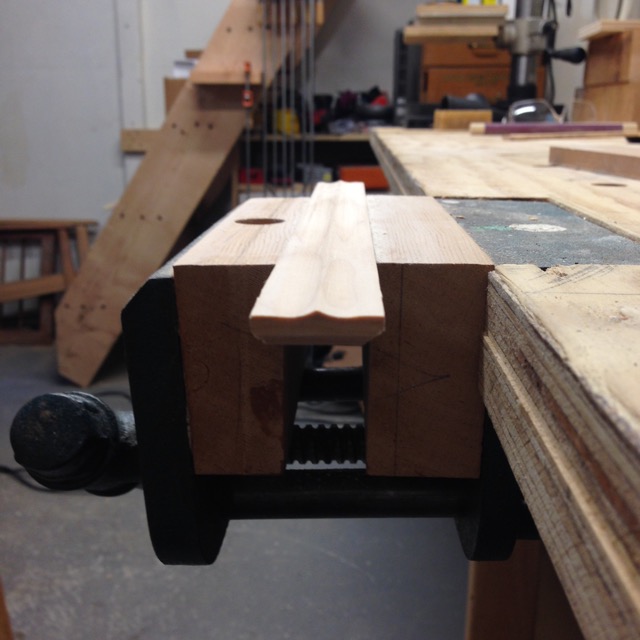

The individual key pieces are cut and laid out side-by-side to make a larger surface. A finished instrument would have the grain continuous but for this prototype we don't care.

Next comes gluing to the sensor stack to test the feel.

interesting a 5 by 4 grid... or is it just a small section for prototyping?

and the cells are independent, will the sensor stack be too? to avoid 'bleed' between cells, or your thinking an independent top layer will reduce this as it doesn't pull down adjacent cells?

does this fit on to your curved surface you showed previously :)

looking forward to see how this goes.

It's just a small section to test. And one test out of many so we can't read too much into it. :-)

Is this still happening? When I last asked, Model B was planned for late summer 2015! :D

Yes, it's still planned. Sorry, I should never mention upcoming dates unless things are nearly done.